Lastest News

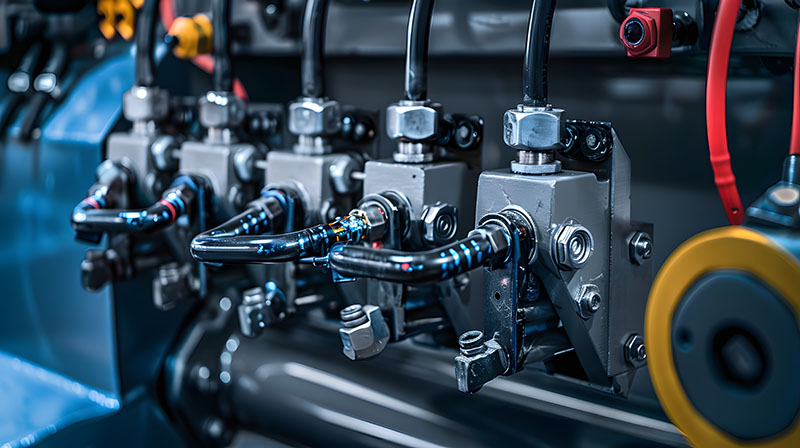

Enhancing Hydraulic System Reliability

4 September 2024

In today’s fast-paced industrial landscape, minimizing downtime is crucial for maintaining productivity and profitability. Hydraulic systems play a vital role in numerous industries, from manufacturing to material handling, and unexpected failures can lead to costly disruptions. This is where a robust preventative maintenance program becomes essential. At Hydraulic Solutions, we offer tailored maintenance plans designed to keep your hydraulic systems running smoothly, reducing the risk of unexpected breakdowns.

Our Preventative Maintenance Program involves regular inspections and servicing by our expert technicians. During these visits, we meticulously check for signs of wear, fluid contamination, and potential component failures. By addressing issues early, we help you avoid more significant problems down the line, ensuring your operations stay on track. This proactive approach not only saves money in the long run but also enhances the safety and reliability of your systems.

In addition to inspections, our program includes fluid analysis and filter changes, essential tasks that help maintain optimal system performance. By regularly monitoring fluid quality, we can detect contaminants that might compromise efficiency and lead to premature wear. With our comprehensive approach, you gain peace of mind knowing that your equipment is in expert hands and performing at its best.

At Hydraulic Solutions, we’re committed to keeping your operations running smoothly with minimal disruption. Our Preventative Maintenance Program is designed to be flexible and tailored to your specific needs, ensuring that your systems remain efficient and reliable. By investing in regular maintenance, you’re investing in the long-term success of your business. Contact us today to learn more about how we can help safeguard your hydraulic systems.